Did you know that aluminum cans, copper wires, and titanium parts can be recycled and reused endlessly? Non-ferrous metals—metals that do not contain iron—play a critical role in modern industries. From construction and electronics to aerospace and renewable energy, these metals are the backbone of countless applications.

Processing non-ferrous metals isn’t just about turning scrap into usable materials; it’s about creating economic value and environmental sustainability. With growing global demand for high-quality processed metals, businesses and recyclers are now investing in advanced methods to maximize metal recovery and quality.

Non-ferrous metal processing reduces reliance on mining, saves energy, and lowers carbon footprints, making it an essential part of both industrial growth and environmental stewardship. Whether you are a manufacturer, recycler, or hobbyist, understanding the value and techniques of non-ferrous metal processing can open doors to profit, efficiency, and sustainability.

What Is Non-Ferrous Metal Processing?

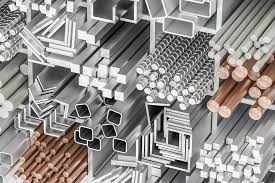

Non-ferrous metal processing is the conversion of raw or scrap metals into usable, high-quality materials. Unlike ferrous metals, which contain iron and are prone to rusting, non-ferrous metals such as aluminum, copper, and titanium are corrosion-resistant, lightweight, and highly conductive, making them ideal for industrial use.

Common Non-Ferrous Metals and Their Uses

- Aluminum – Lightweight, corrosion-resistant, used in aircraft, packaging, and construction.

- Copper – Excellent conductor, widely used in electrical wiring, plumbing, and electronics.

- Nickel – Adds strength and corrosion resistance to stainless steel, batteries, and alloys.

- Lead – Dense and malleable, used in batteries, shielding, and industrial applications.

- Zinc – Mainly used for galvanization to prevent steel corrosion and in alloys.

- Titanium – Extremely strong and lightweight, used in aerospace, medical implants, and high-end engineering applications.

Purity, Quality, and Recyclability

The value of non-ferrous metals depends on purity and quality. Contaminated scrap or alloyed metals may require additional processing, which can lower resale value. Proper sorting, cleaning, and grading of metals enhances their usability and market price.

Key Techniques in Non-Ferrous Metal Processing

Processing non-ferrous metals involves several techniques to convert scrap or raw metal into usable products. Here’s a closer look:

1. Melting and Casting

This involves heating scrap or raw metal until it melts, then pouring it into molds to create ingots, sheets, rods, or other forms. This method allows recyclers to transform low-grade scrap into high-value, usable products.

2. Electrolysis & Refining

Electrolysis is used primarily for purifying metals like copper and aluminum. By passing an electric current through a solution containing the metal, impurities are removed, producing high-purity metal suitable for industrial use.

3. Rolling, Extrusion & Sheet Formation

Once metals are purified, they can be rolled into sheets, extruded into rods, or drawn into wires. These processes improve metal uniformity and make it suitable for industrial and commercial applications, from construction panels to electrical wiring.

4. Scrap Metal Recycling

Recycling is one of the most important aspects of non-ferrous metal processing. Scrap metals such as wires, cans, pipes, and industrial waste are collected, sorted, cleaned, and processed. Efficient recycling reduces environmental impact and provides a steady supply of high-quality metals.

Impact on Quality and Usability

Each processing step—from melting to refining to rolling—affects metal purity, mechanical properties, and market value. Modern technologies ensure that non-ferrous metals retain their key properties, making them suitable for even the most demanding applications.

Why Non-Ferrous Metal Processing Matters

Non-ferrous metal processing is not just a technical procedure; it’s a critical economic and environmental activity.

Economic Benefits

- High Demand: Non-ferrous metals are used in electronics, renewable energy, aerospace, and automotive industries.

- Cost-Efficient Recycling: Using scrap metals reduces costs compared to mining new materials.

- Manufacturing Efficiency: Processed metals are uniform, high-quality, and ready for production.

Environmental Benefits

- Reduces Mining Waste: Recycling non-ferrous metals minimizes the need for new mining, conserving natural resources.

- Lowers Carbon Footprint: Producing recycled metals requires less energy than extracting and refining ores.

- Promotes Sustainability: Continuous recycling ensures metals remain in circulation for decades.

Industries Reliant on Processed Non-Ferrous Metals

- Automotive and transportation

- Aerospace and defense

- Electronics and telecommunications

- Renewable energy (solar panels, wind turbines)

- Construction and infrastructure

Non-ferrous metal processing is a bridge between industrial demand and environmental responsibility, making it a profitable and sustainable sector.

How to Get Started or Invest

Whether you are a business, recycling center, or hobbyist, non-ferrous metal processing offers opportunities for profit and sustainability.

Tips for Businesses and Recyclers

- Source Quality Scrap: Collect clean aluminum, copper, and other metals.

- Invest in Modern Equipment: Melting, refining, and extrusion equipment improve efficiency and product quality.

- Follow Market Trends: Track global metal prices to sell at optimal times.

- Maintain Quality Standards: Proper grading and processing enhance resale value.

Tips for Hobbyists and Small-Scale Investors

- Start by collecting household scrap metals.

- Learn basic sorting and stripping techniques to increase value.

- Partner with licensed recyclers to sell processed metals.

FAQ

1. What is non-ferrous metal processing?

It’s the process of converting scrap or raw non-ferrous metals (aluminum, copper, zinc, etc.) into usable, high-quality materials for industry.

2. Which metals are non-ferrous?

Common non-ferrous metals include aluminum, copper, nickel, lead, zinc, and titanium. These metals do not contain iron and resist corrosion.

3. Why is non-ferrous metal processing important?

It supports high-demand industries, reduces mining waste, lowers carbon footprints, and creates profitable recycling opportunities.

4. What are the main processing techniques?

Melting and casting, electrolysis and refining, rolling and extrusion, and scrap metal recycling are the core techniques.

5. How can I invest in non-ferrous metal processing?

Start by sourcing clean scrap metals, investing in processing equipment, following market trends, and maintaining quality standards for resale.

Call to Action

Explore non-ferrous metal processing today to turn scrap into profit while supporting a sustainable future. By combining industry knowledge, smart processing techniques, and eco-conscious practices, you can make a tangible impact on the economy and the planet.

Non-ferrous metal processing is more than a business—it’s a pathway to profit, sustainability, and technological innovation. From aluminum cans to titanium parts, these metals can be recycled endlessly, creating value for industries and individuals alike. Whether you are starting a recycling venture or expanding an industrial operation, understanding and investing in non-ferrous metal processing ensures you are part of a growing, profitable, and environmentally responsible market.